Die-Cut Machines for Corrugated Boxes

Die-cut machines are essential tools in the corrugated packaging industry, allowing manufacturers to create custom shapes and sizes of corrugated boxes. These machines use precision cutting dies to cut, shape, and crease corrugated boards into intricate designs that standard box-making methods cannot achieve.

What is a Die-Cut Machine?

A die-cut machine is a device that uses a die—a specialized tool with a sharp edge—to cut and shape materials. In the context of corrugated boxes, die-cut machines are used to produce boxes with unique shapes, perforations, and intricate designs. This process ensures high precision and consistency, which is critical for creating packaging that meets specific requirements.

Types of Die-Cut Machines

There are several types of die-cut machines used in the production of corrugated boxes:

- Flatbed Die-Cut Machines:

- Description: Flatbed die-cutting involves a flat cutting die and a flat surface onto which the material is placed. The die presses down onto the material, cutting it into the desired shape.

- Advantages: Provides high precision and is ideal for complex shapes and detailed designs. Suitable for both small and large production runs.

- Applications: Used for producing custom packaging, display boxes, and intricate designs.

- Rotary Die-Cut Machines:

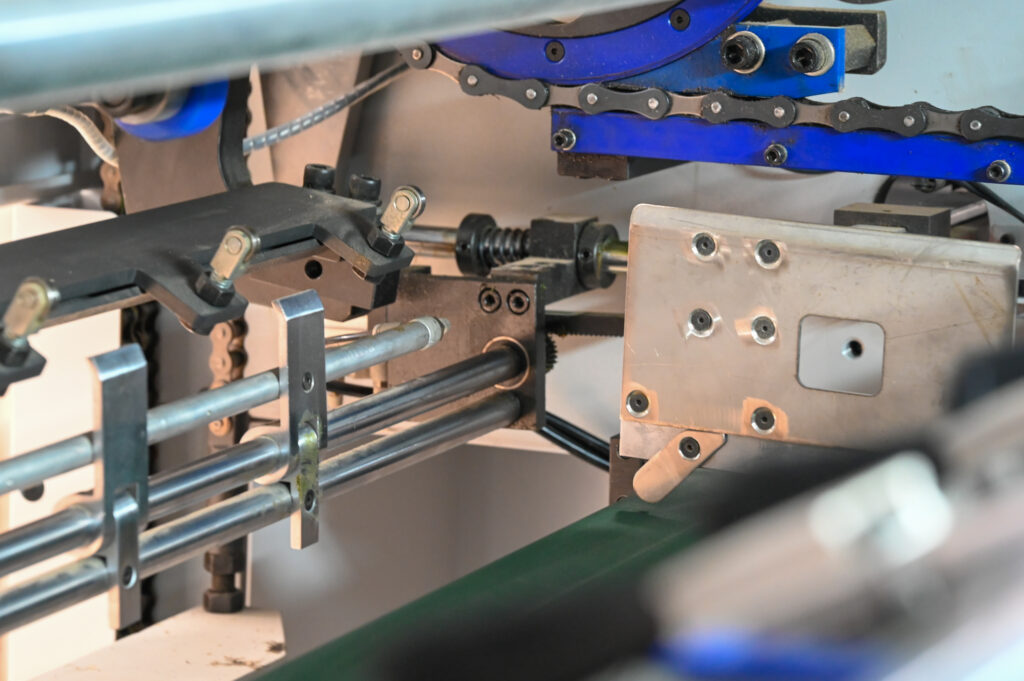

- Description: Rotary die-cutting uses a cylindrical die that rotates as the material passes through the machine. The die cuts the material as it moves along a conveyor belt.

- Advantages: Offers high-speed production and is efficient for large volumes. Can handle continuous cutting, making it suitable for high-output operations.

- Applications: Commonly used for producing large quantities of corrugated boxes, including standard shipping boxes and packaging inserts.

- Laser Die-Cut Machines:

- Description: Laser die-cutting uses a high-powered laser to cut and shape materials. The laser follows a programmed design to create precise cuts without the need for physical dies.

- Advantages: Provides unmatched precision and flexibility. Can handle intricate designs and quick changes without the need for new dies.

- Applications: Ideal for prototypes, short runs, and highly detailed designs.

Key Features of Die-Cut Machines

When selecting a die-cut machine for corrugated boxes, several important features should be considered:

- Precision: The machine should offer high accuracy to ensure that each box is cut exactly to specifications.

- Speed: High-speed machines can increase productivity and reduce lead times.

- Versatility: The ability to handle different types of corrugated board and create a variety of designs is crucial for meeting diverse packaging needs.

- Ease of Use: User-friendly machines with easy setup and maintenance can improve efficiency and reduce downtime.

- Cost-Effectiveness: The machine should offer a good balance between initial investment, operating costs, and production output.

The Die-Cutting Process

The die-cutting process involves several steps to transform corrugated board into finished boxes:

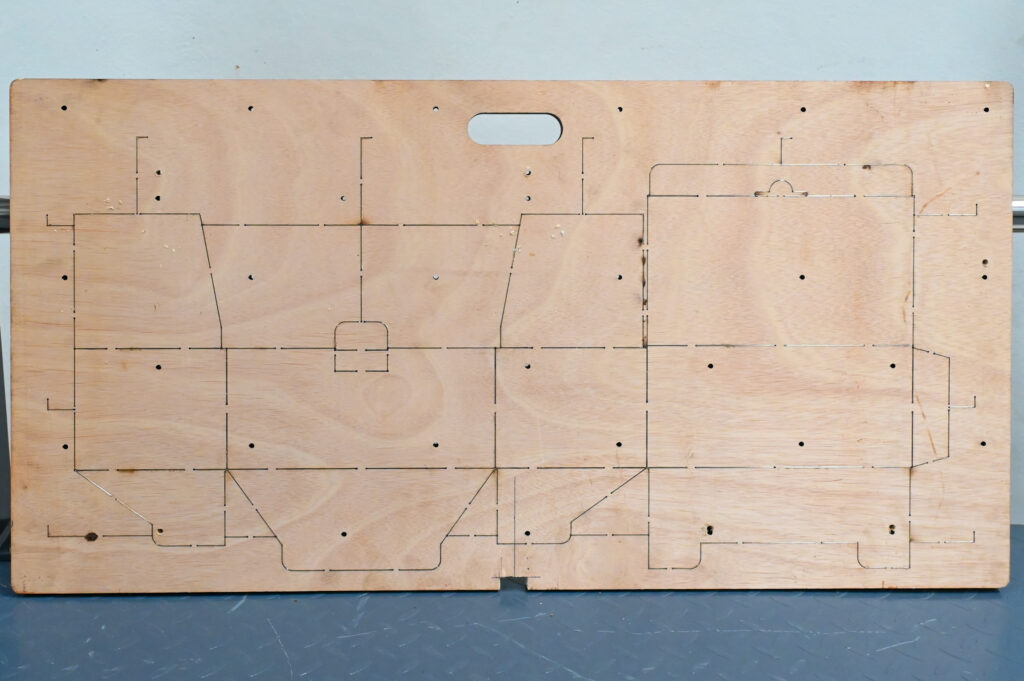

- Design Creation: A custom design is created using specialized software, detailing the shape, size, and features of the box.

- Die Preparation: For flatbed and rotary die-cutting, a die is manufactured based on the design. For laser die-cutting, the design is programmed into the machine.

- Material Setup: The corrugated board is loaded into the die-cut machine.

- Cutting: The machine cuts, shapes, and creases the board according to the design.

- Finishing: The cut pieces are removed from the machine, inspected for quality, and assembled into finished boxes as needed.

Benefits of Die-Cut Corrugated Boxes

Die-cut corrugated boxes offer several advantages:

- Customization: Die-cut machines can produce boxes in any shape or size, allowing for tailored packaging solutions.

- Efficiency: Die-cutting can produce large quantities of boxes quickly and accurately.

- Versatility: The ability to create unique designs, perforations, and features enhances the functionality and appeal of the packaging.

- Quality: Die-cut boxes have precise edges and consistent dimensions, ensuring a professional appearance and reliable performance.

In summary, die-cut machines are vital for producing custom corrugated boxes that meet specific design and functional requirements. By utilizing advanced die-cutting technology, manufacturers can create high-quality, tailor-made packaging solutions that enhance product presentation and protect contents effectively.